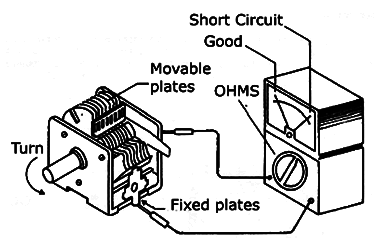

There are several problems that can occur with variable capacitors used in tuning circuits. For the old types, the main problem is bend in the plates causing the component to short and thus inoperative. This short can be detected as shown in Figure 1.

Around the all turn of the variable capacitor must have no indication of low resistances.

The needle of the meter should remain on infinit to a variable in good condition. A first step to be taken if it is found a short between the plates is to try to correct the alignment of these plates by the screw that exists in the mobile variable axis.

Pressing and releasing this screw it is possible adjusting the plates if they are bent. If the plates are bent, very carefully the technician can attempt to correct the defect, always making a continuity test to detect the moment when the component is recovered.

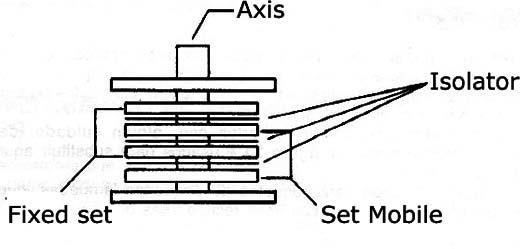

For small variable short problem can be in the insulating sheets inside them.

Dismantling the component very carefully you can get the defective sheets and try to correct the defect or with insulating use of other variables that are abandoned by the same problem or even with the improvisation of insulating sheets. In figure 2 show how the metal plates are placed having between them an insulating foil that must avoid contact between the mobile assembly and the fixed assembly.

After reassembly should be done an isolation test to check if the short between the plates was really removed. If the problem is moisture or dirt, the variable can be disassembled for a cleaning, but always careful not to bend plates and not forget any insulating sheet at reassembly.