Researches carried out in botanical laboratories of famous universities revealed a sensitivity manifested by many species of plants to electrical stimuli.

Tomato plants, for example, may bear larger fruits and in less time, if subjected to magnetic fields of some orientation, while many other vegetables can be stimulated to grow faster and thus become more beautiful in less time by electric field action.

Although an action in these fields does not have well-established laws and there is no knowledge about which plants have more or less sensitivity, a reader's ability to have, at home, a generator able to produce intense fields, opens fascinating possibilities for discoveries of effects .

If the reader is attracted to research in this area, likes to experiment with plants, here is a possibility to have a device at home that has led to the domains of bioelectronics or simply "bionics."

The apparatus described in this article is very simple to assemble and uses low cost components which allows its realization even by the fact that there is no previous experience in electronics.

In fact, because it is a device whose applications may interest a much wider audience besides the one specifically connected electronics, we make a description of the design so as to make the assembly accessible to all.

Just read the article and follow the instructions that surely a assembly will be a success.

We also anticipate that even generating a very high potential, between 5 and 10 kV the device is perfectly safe to use, and the energy consumption is minimum and can then let it be permanently connected.

The plants subjected to its influence do not suffer any damage, but only an influence of the electric field that manifests itself in changes of behavior that characterize the study that we propose to the readers (Figure 1).

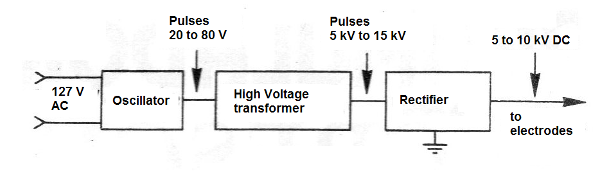

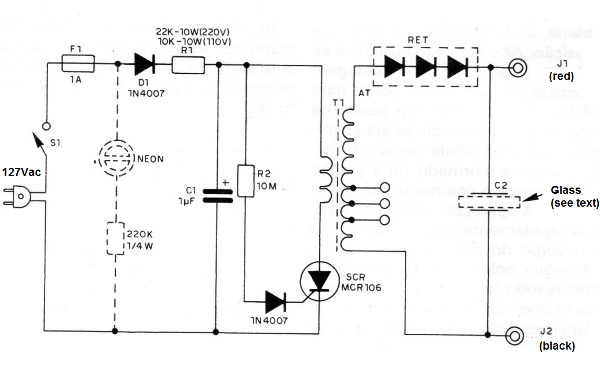

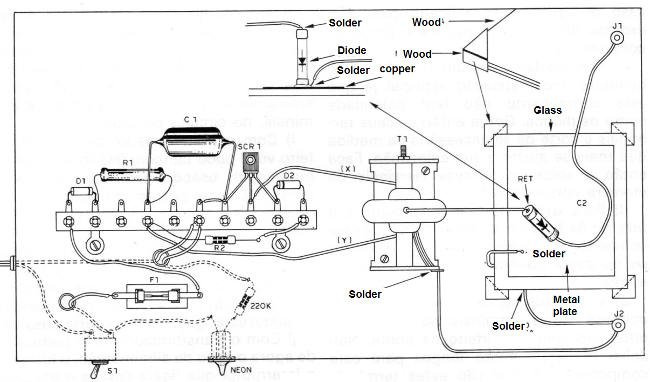

In Figure 2 we have a simplified diagram of this instrument to analyze its principle of operation.

It is basically an electronic oscillator which works from the local power grid (110 or 220 V). This oscillator produces pulses of short duration which, when applied to a special transformer, produces an output voltage between 5 and 10 000 volts.

This voltage is, however, obtained alternately and must be rectified to produce a necessary constant field to the proposed experiments.

Let’s analyse the operation of each of the phases of the circuit.

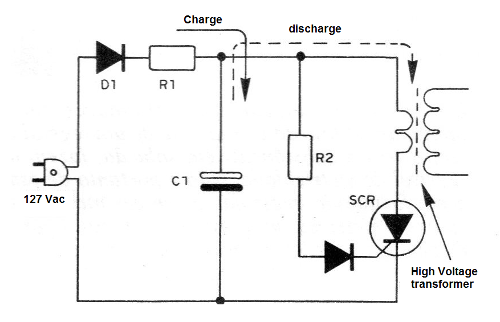

The oscillator used in the input is based on a silicon controlled diode (SCR) which is a high speed solid state switch.

The alternating current of the network is then rectified by a common diode and a capacitor is applied which then charges gradually.

As the capacitor is charged, the voltage across its terminals is raised to the point where the SCR triggering voltage is reached.

At this point the SCR "switches on" entirely and the load represented by the capacitor can drain through it to the primary coil of the high voltage transformer. Figure 3 shows this basic circuit with the directions of the charge and discharge currents.

The discharge of the capacitor is fast so that the pulse produced has good energy to thereby achieve a desired high voltage without a secondary transformer.

With the capacitor discharged, the SCR shuts off and a new cycle starts.

The charge velocity of the capacitor therefore determines the number of pulses that we will have in each second. Using a high value resistor in series with the capacitor can get one or two pulses every 5 seconds which is more than enough to keep a constant charge level of the capacitor that will be placed at the high voltage output circuit.

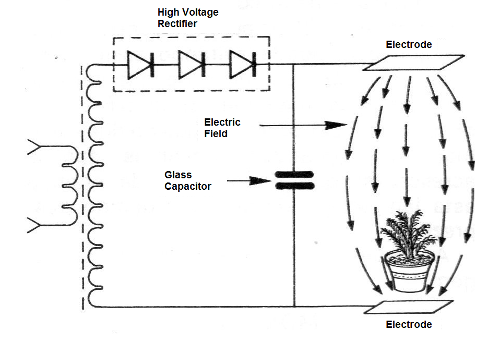

See that the voltage obtained in the transformer secondary is pulsating and must therefore be rectified so that we can have a constant potential and thus a constant field for the experiments.

This is achieved by a high voltage diode connected to the transformer, which carries a capacitor made of glass sheets.

In this diode that will be connected to the electrode will produce the field, and to supply the charges that naturally escape into the air through this electrode, the capacitor remains charged. (Figure 4)

See then that the circuit functions as a "pump" which in each pulse sends a certain amount of charge to the glass capacitor which then gradually flows into the air keeping the field constant.

OBTAINING COMPONENTS

The components used in this assembly are all very common, and there is even the possibility that some of them may be reused of old televisions and other abandoned devices.

As we said, however, as this device is intended for an audience that normally may not be connected to electronics we will give instructions on how to get the components, as clear as possible.

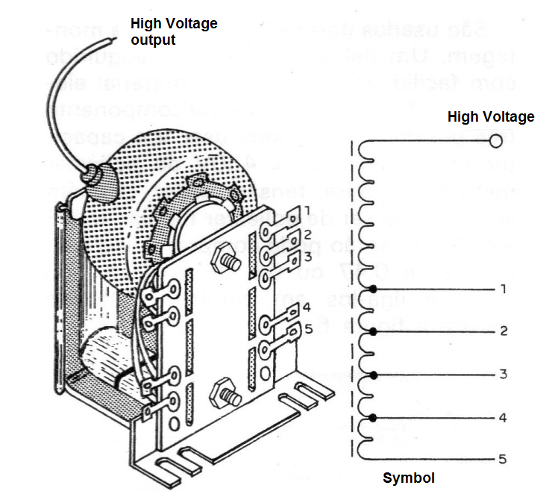

The main component for this assembly is the high voltage transformer or flyback, whose appearance is shown in Figure 5.

This transformer is used in analog TV sets and old computer monitors to produce the high voltage required to operate the imaging tube.

The reader can find this transformer in the "black box" of high voltage of an old TV, and if there is a device of this abandoned we can take advantage of this component.

For those who want to get the flyback or horizontal output transformer, just go to any electronics store and ask for this component.

Any type (open) is good since the device is not critical and what interests us is only its secondary winding.

SCR (Silicon Controlled Diode) is a component that can be easily achieved in electronics houses. In particular we recommend using the MCR-106 or TIC106 for 200 V, but equivalents like IR106 or C106 can be tried.

The diodes D1 and D2 are of the 1N4007 type, but there are several equivalents that can be used. The most common is the BY127.

The wire resistor R1 determines the frequency of the pulses in the transformer and, therefore, the energy consumption of the apparatus. You can use a 10 k to 22 k resistor (you can experiment) with a 5 W dissipation. (Ask the store for a 10 k x 5W wire resistor and the seller will know what to give you.)

The other resistor, R2 is 4.7M x ¼W coal, and is very common.

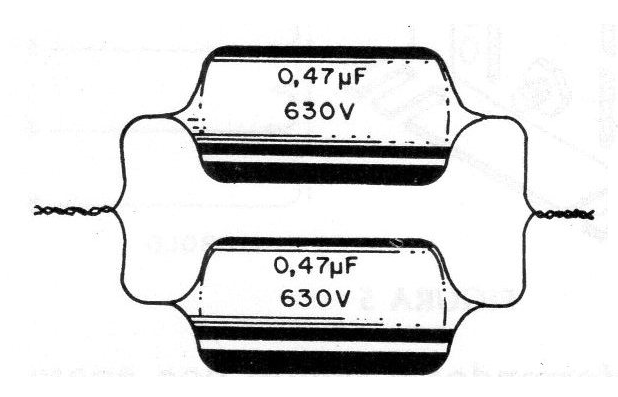

Two capacitors are used in this assembly. One of them, C1 can be easily purchased in electronics houses.

The reader has three possibilities for this component: you can use a single capacitor of 1 uF x 450 V of metallized polyester (for higher voltage also works), it can be tubular polyester of 1uF x 63oV or you can buy two capacitors of 0.47 or 0.5 uF x 450 V (or more) and connect them in parallel as shown in Figure 6. (*)

(*) Nowadays 1 uF polyester capacitors can be found easily.

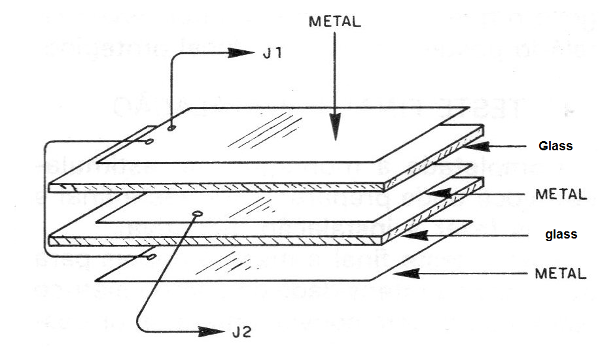

The other C2 is a "manufactured" capacitor with three sheets of aluminum or any other metal (of any thickness) and two sheets of glass.

In the part concerning the assembly we will give instructions as to the dimensions of the sheets of glass and the sheets of metal that form their armor.

The high-voltage rectifier is a component often used in many TV sets and can thus be easily found in electronics houses.

Any rectifier for a voltage of at least 10 kV (10 000 volts) is used, and there is no special recommendation for the type.

Finally, we have the complementary components of this assembly that is the box or base in which the assembly will be installed, which can be of wood or any other insulating material, the power cable that can be made or acquired ready, the fuse that must be equipped with a special holder, and the switch that turns the unit on and off.

As an additional suggestion to increase the safety of the operation, the connection of a standard neon lamp in series with a 220 k resistor to indicate when the unit is connected prevents accidental shocks in the high voltage sector.

This lamp marked NE-1 and the 220 k resistor are included in the diagram, but are optional. We should only add that the energy consumption of this lamp can be considered insignificant.

The following are the assembly instructions:

ASSEMBLY

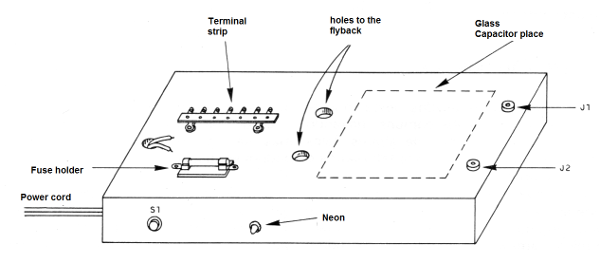

As a basis for fixing the components the reader can use a board of 30 x 10 cm or a box of the same dimensions, approximately 5 cm high, as suggested in Figure 7.

The electronic components, except the high voltage transformer, will all be welded on a terminal bridge (which can be purchased at electronics houses) and this bridge will be secured with bolts and nuts.

For the assembly work you will need to use a small, good quality iron welder, side cutting pliers, thin-tipped pliers, a wire stripping blade and a screwdriver.

The complete diagram of the apparatus is shown in Figure 8.

The assembly on the terminal bridge is shown in Figure 9.

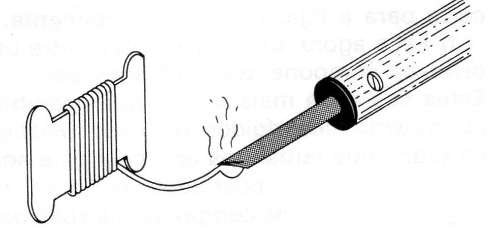

For the welding, start by heating the iron well for at least 5 minutes, then stab its tip. To tin up do as follows: wipe the tip of the hot iron by passing a thin file or sandpaper, cleaning only a small area of ??it (Figure 10).

Then just touch some weld on it so that it melts on the welder tip. With this, the iron is ready to be used.

The sequence of operations for the assembly is as follows:

A) Weld the SCR by observing its position well. Open its terminals a little if they do not fit the bridge and at the welding, touch the iron at the bridge terminal to warm it up, then put some weld so that when it fuses it involves both the bridge terminal and the terminal of the component making a firm junction. Do not move the component until the weld cools. The welding operation must be done quickly so that the heat does not reach the body of the component.

B) Then weld the two diodes, D1 and D2, observing their positions well, since if there is a reversal, the unit will not work as there will be the danger of damaging certain components. When welding the terminals of the diodes proceed as in the case of the SCR taking care, so that the excess heat does not reach the body of the component.

C) To weld resistor R1 there is no special recommendation since this component does not have polarity like the diodes. Then fold up its terminals and cut them if necessary as you adjust its placement. Then weld these terminals in the conventional manner.

D) To weld R2 the procedure is the same as R1, except that this component is more delicate. Avoid excess heat by welding quickly.

E) You can now weld the capacitor by folding its terminals so as to get a perfect fit on the bridge. Do not leave very long terminals for this component, because it is these terminals that must support it. If they are too long there may be a risk of folding and breaking during transport or handling. There is no proper polarity for the connection of this component.

F) Now make the interconnections between the various components, indicated by wires. These wires are nothing more than coats or even rigid plastic wires cut into the appropriate sizes and welded at the locations shown in the figure.

G) With all the welded components on the bridge you can make its fixation in the assembly base, now working on the other components. We started with flyback.

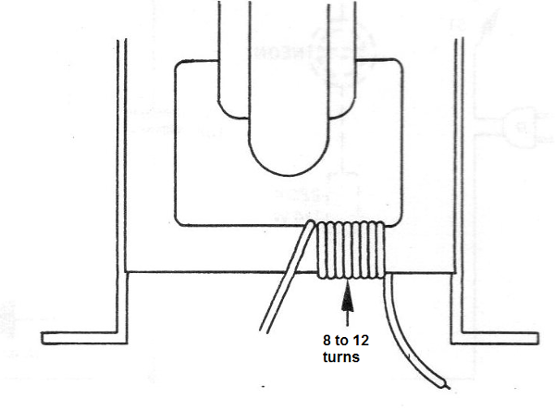

H) You should make the primary winding of your high voltage transformer by winding a few turns of wire the way shown in Figure 11. All this is very easy.

Simply wind from 8 to 12 turns of common connecting wire of plastic cover (you do not need to remove the cover) keeping the turns together. If you use hard wire it is easier to do the winding. The ends of this winding will be connected to the terminal bridge, on the main circuit.

With the high-voltage transformer made, you can also secure it at the assembly base, using for this purpose screws like nuts placed in one or two of its many holes from the bottom.

Only after attaching this component, you should weld the ends of the coil from the primary to the terminal bridge, cutting the excess of the cable in such a way as to keep this connection as short as possible.

J) With the transformer in the circuit, now weld the power cord, the fuse and the switch that turns the unit on and off. If your assembly uses the neon lamp as an indicator, you can now proceed to the placement of this component and the resistor associated with the circuit.

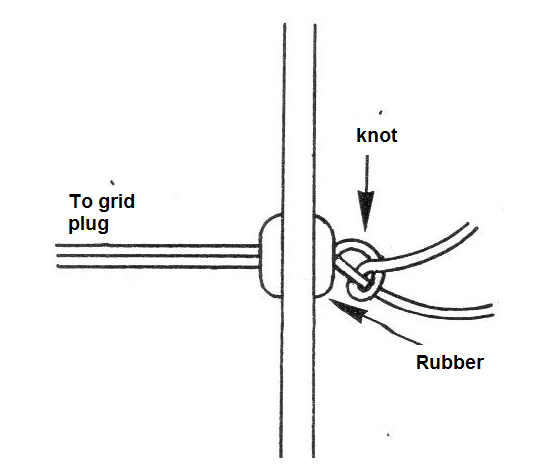

Make sure that the power cord is securely attached in such a way that any pulling in the handling will not force the points of its connection. Passing the wire under the assembly base and securing it in a clamp with a protective node will be a good installation technique, as suggested in Figure 12.

The switch should be located at a point on the accessible assembly base preferably with the indicator lamp nearby. For the version that uses a simple wooden base, make a panel with a slat of about 10 cm in length, while in the case of the box, the installation of this switch can be made on one side.

The fuse holder may be of the internal assembly type, shown in the figure which illustrates the entire "clad" apparatus.

K) Once this phase of the assembly is completed, before the installation of the high voltage rectifier, glass capacitor and other components, the reader can already perform a functional test.

INITIAL OPERATIONAL TEST

Check all the connections, and if everything is in order, connect the power cord to the network (110 or 220 V, according to your case). Immediately the device should start up when S1 is activated, which will be characterized by a noise similar to a hissing emitted by the high voltage transformer.

Watch out! Do not touch any part of this component as you may experience an unpleasant shock.

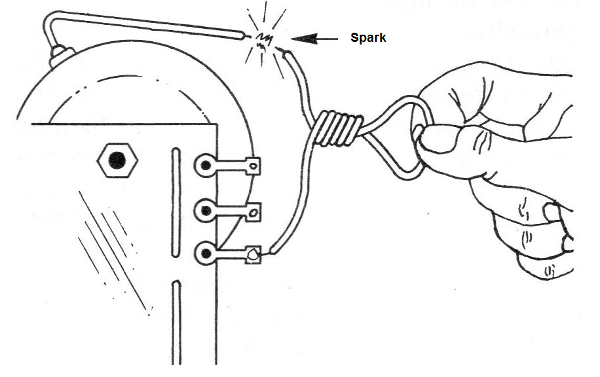

Then take a piece of an ordinary plastic cover wire and pull its tips on the high voltage terminal of this transformer and the innermost terminal of the same coil as shown in Figure 13.

As you approach a continuous spark should jump from 0.5 to 1.5 cm in length.

If this happens, the device is working.

If the flyback does not oscillate, that is, there is no noise emission, the first component that you should check is the SCR.

Remove it from the circuit and test it. If you do not have this possibility, it will be convenient to put another SCR in the circuit, because small differences in characteristics one from the other can sometimes make it difficult for some to oscillate and not for others.

Also check the connections of the capacitors, diodes and resistors and especially the coil ends of the transformer primary.

SECOND PART OF THE ASSEMBLY

With the device oscillating conveniently you can proceed to the assembly, now making the installation of glass capacitor and high voltage rectifier diode.

The capacitor consists of two 9 x 9 cm (2 mm thick or larger) glass plates and three 8 x 8 cm metal plates (copper, tin or foil).

In Figure 14 we have the way of building this capacitor.

Its attachment to the assembly base can be made by any insulating material, or even glue.

Note that once the capacitor has been attached to the connecting wires, we can do the welding of the high voltage rectifier diode. For this we must observe the polarity, orienting ourselves by the symbol drawn in its body.

One of the diode terminals is welded to the transformer high voltage wire, and the other is welded to the terminal bridge attached to the base.

From this terminal, the wire goes to the central board of the glass capacitor while the connecting wires of the outer boards of the capacitor must be welded to the terminal of the transformer, which corresponds to the innermost wire of its high voltage coil.

In the assembly base, two isolated jacks or terminals, given by J1 and J2, will be attached to the drawing to be connected by wires, one to the point where the diode is attached to the terminal bridge, and the other to the negative pole of the circuit, to the innermost wire of the fly-back. The drawing shows all this clearly.

In these two jacks, the electrodes will be connected, which will produce the field on the plants undergoing experimentation.

With all this built, the reader can make the final installation of the circuit and even carry out the assembly of a field indicator to get an idea of ??its influence.

Remember that on the power grid of 110 V/127 V with a resistor of 10 k in the input, the device consumes only 1.21 watts, which means that the expense that the reader will have with it in 5 days connected in a roll is the same as a 60 W lamp would in 1 hour!

The same consumption is valid for a 22 k resistor in the 220 V circuit.

Note: it is important to note that in the high voltage part, an accidental contact is dangerous, which means that the reader must install it at a protected location.

FINAL TEST AND INSTALLATION

Completing the stimulator assembly, you can prepare your final test and then do the final installation.

For the final test, and even afterwards to evaluate the intensity of the stimulating electric field, it will be convenient for the reader to have an indicator.

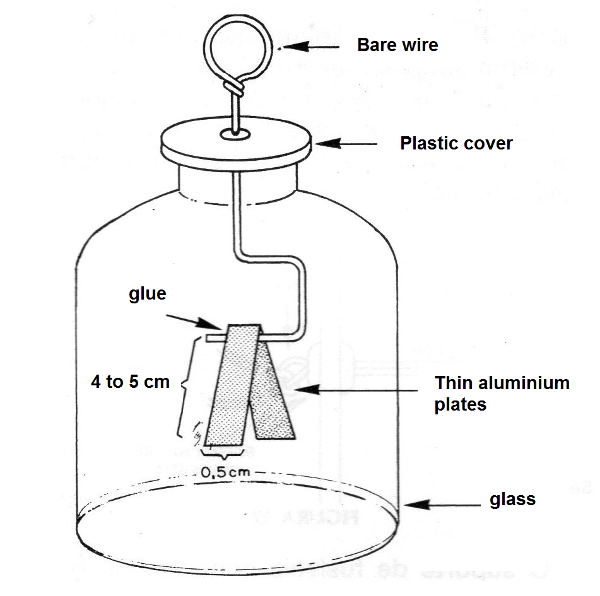

This can be easily built with a piece of wire, a small flexible aluminum foil and a clear canning glass with a plastic lid.

What we propose to the reader is the assembly of a simple sheet electroscope which is shown in Figure 15.

The cord ending at the top, in the form of a pick-up link, descends into the canning glass ending in the shape of a hook.

In this hook, with some glue, it is attached to a small aluminum blade (as thin as possible) folded in V.

The principle of the operation of this electroscope is simple: when subjected to an intense field there is the induction of charges in the capture link and consequently in the slides.

As the charges that the blades acquire have the same signal, there is a repulsion force between them that causes them to open. In short, the more intense the electric field, as we approach the electroscope, the greater the movement of the aluminum blades in the direction of opening them.

Then, by attaching a wire approximately 1 meter long, stripped to the terminals of the stimulator J1 or J2, as we approach the electroscope, we will notice the opening of the blades indicating the presence of a strong electric field.

The field must manifest in both jack J1 and J2, with the difference only that in one case the producing charges will be positive and in the other negative.

Once the operation is verified, the reader can prepare the location of his experiments by permanently installing the device in it.

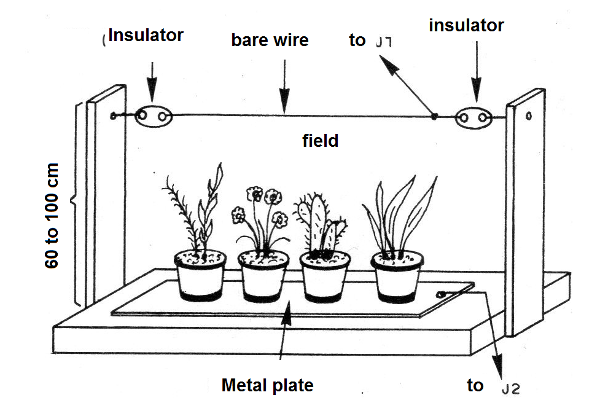

Under the place, where the pots stay with the plants, should be placed a wire mesh or metal base where one of the wires of the stimulator will be attached to.

And, on plants, at a height of not more than 1 meter from them should be extended, one or more peeled wires, isolated at the tip by a ceramic nut or insulator, as shown in Figure 16.

If we connect jack J1 to the upper wire and J2 to the base, the field will be directed from top to bottom, that is, we will have a higher potential at the top and a lower potential at the bottom.

In the same way, the inversion of the connections can be made to change the influence of the field.

Once installed, the reader can easily verify the presence of the field in place by the leaf electroscope.

As the power consumption of the device is extremely low, approximately 1.2 W, it can be permanently connected without problems.

Caution: Do not touch the high voltage wires when the appliance is switched on.

EXPERIMENT

The kind of influences electric fields can have on plants is still unknown. Although many experiments are being carried out in many laboratories, the results are still not fully confirmed and very little has been published about them.

The reader interested in this type of research undoubtedly has a fascinating field of work, determining the species that may eventually manifest any major reaction to the influence of electricity.

However, it should be noted that in order to achieve positive results in these surveys, it is necessary to know how to proceed.

Do not just put your plants under the device and "see what happens".

The procedure for a researcher who wants to do their experiments carefully is not this.

The results can only be considered positive if there is a comparison between what happens with normal growing plants and the influence given by the field.

For those who wish to develop a research, which is the reason for an excellent school work, here is our suggestion.

Plant seeds in many pots, beans, for example, and place half of the pots under the influence of the field and the other half away from their influence.

Then, as the plants sprout and grow, compare the growth obtained in both cases, taking the averages of the values ??obtained for the plants under the influence of the field and out of its influence.

All vessels should be irrigated with the same amount of water and receive the same amount of light so that other influences do not alter the results of the experiments.

More advanced researchers may even check the possibility of genetic changes occurring under the influence of the field by analyzing several generations of certain plants.

SCR - MCR 106, IR106 or C106 - silicon controlled diode

D1, D2-1N4007 or BY127 - silicon diode

R1 - 10 kV 10 W for 110 V or 22 kV 10 W for 220 V

C1 - 1 uF - see text - capacitor

R2 - 10 M - ¼ W resistor

T1 - Flyback (see text)

C2 - glass capacitor

RET - high voltage rectifier - see text

J1, J2 - insulated terminals or output jacks

F1 - 1 A fuse

S1 - single switch

Miscellaneous: neon lamp and 220 k x 1/4 W resistor; terminal bridge, base for the assembly or housing, wires, power cord, welder, screws and nuts, fuse holder, etc.

FOR THE ELECTROSCOPE

1 tinned glass with a plastic lid

2 aluminum blades

1 piece of 10 cm of hard wire