There are cases where a patient is unable to breathe properly for several reasons. One is the inability to activate the lung so that it pumps air. Another, as occurs in the case of the corona virus, is the presence of secretions that affect the arrival of air in an appropriate way. For these cases, the air must then be pumped so that it reaches the lungs, thus leading to the necessary oxygenation.

For this purpose, medical equipment called pulmonary ventilators and oxygen concentrators are used. Their purpose is to force the external air through pressure to reach the patient's lungs, and to increase the oxygen concentration, thus producing the necessary oxygenation, which is responsible for life maintaining.

Lung ventilators can have the most diverse degrees of complexity. They can be simple pressure pumps, with some control features that prevent excess pressure capable of causing damage, even the most sophisticated ones that increase the oxygen concentration and have features that monitor the oxygenation of the patient thus controlling the air pressure level, in addition to others.

We remember that the air we breathe contains only around 20.8% of oxigen, 78% of which is nitrogen, which is inert and the remaining 2.2% of various other gases such as carbon dioxide, argon, water vapor, etc.

Thus, in a simpler piece of equipment, in which we pump the ambient air itself, we must consider that only about 20% of it is oxygen. In a case where the patient needs more oxygen, the device must be able to concentrate the oxygen as well and not just pump it, so there are resources for that. For that case, we have oxygen concentrators. Let's see how they work.

How they work

In the basic simplest type, what we have is an air pump that removes the air from the environment itself and making it pass through filters and valves that do the dosing, so that excessive pressure does not cause harm to the patient, apply it through a tube to the patient's lung. There are also milder cases where masks can be used.

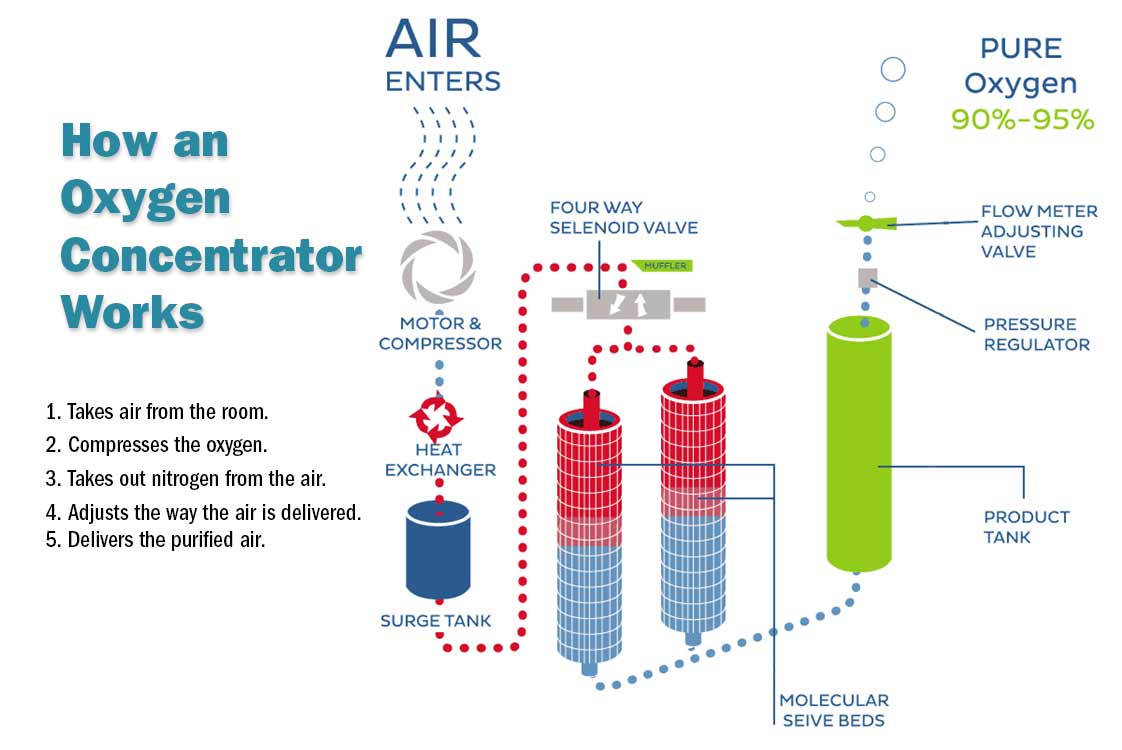

We can, however, have more advanced types in which the oxygen concentration can be obtained and controlled. In this case, we can say that the device is also an oxygen concentrator. A basic type is shown in figure 2. In this type filters are used to concentrate oxygen.

In this type of equipment, we have a motor that drives a compressor to removes air from the environment and uses 4-way solenoid valves to apply it to two filters. The proportion in which the filters act determines the oxygen concentration and can be adjusted to values that reach 95%.

The filters are based on materials called microporous. These materials have pores whose dimensions compare to that of individual atoms or molecules. Thus, a “network” made with these materials can selectively pass through molecules, for example, oxygen, but preventing the passage of other gases. These are called molecular filters.

We then obtain varying degrees of purity oxygen to be then taken to the patient.

Electronics in action

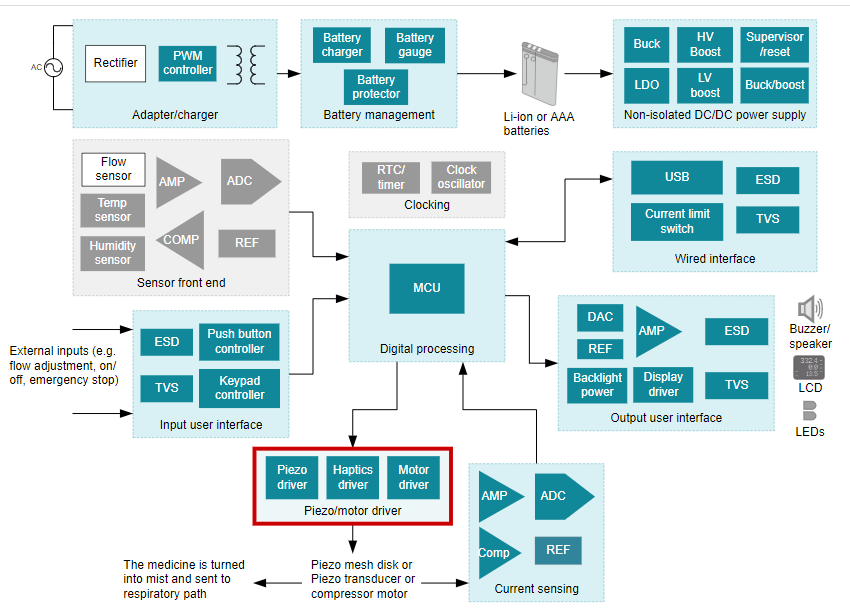

In a more elaborate project, with more electronics, we can add a functionality that leads to more security and better effects. An example is given in the block diagram of a ventilator that also concentrates oxygen, using a microcontroller. (figure 3)

In this project, instead of concentrating filters, an external oxygen source was used to obtain a mixture with the desired proportion.

This proportion is given by information captured by sensors in the patient (oximetry) and taken to a microcontroller. This microcontroller, in addition to determining the proportion of oxygen that must be pumped, also acts on the pressure controls and eventually triggers an alarm if necessary.

In a variation of this project, we can obtain the mixture through a filter, without the need for an external oxygen balloon. Evidently, the values ??of concentrations, pressures, monitored oxygen must be obtained from the appropriate literature, with some available on the Internet, such as the work available at: http://www.peb.ufrj.br/tese/Tese0024_2005_12_09.pdf (in Portuguese)

The UFRJ (*) student project that presents this work, Andrea Fonseca da Cruz, was originally created for small animals, but it serves perfectly as a basis for an advanced project like the one below.

Advanced Project

In an article in which we deal with medical equipment designs with Texas Instruments components, we gave an example of a sophisticated oxygen concentrator, fully supported by the company. The block diagram of this respirator (ventilator) or oxygen concentrator is given in figure 4.

In this project, obviously, the central element is the microcontroller. Going to the Texas website and clicking on the microcontroller, we find that there are many options for a designer. It can use a simpler microcontroller with wired connections to peripherals, both in low-power versions for a portable device, as well as normal ones. Processing capacities may vary.

In the same way, we have connectivity options, such as sensors or access to sensors or to a WiFi network wireless allowing to send data in real time to a medical team. Imagine the medical team having access to each patient using the device on their cell phones, receiving real-time information and even alerts.

In this same diagram we also have control options for the used motors that can be of the most diverse technologies such as stepper motors, brushless motors, common brushed motors, etc.

And, of course, we still have supporting components such as those that are part of a power supply, protection components against surges in the power grid, operational amplifiers to be used with sensors, effectors and much more.

There are also specific applications that are available, for example, the circuits used in oximetry, temperature measurement, pressure measurement and much more.

See that the sophistication of the project can reach high degrees, depending on what is desired. From a simple machine with the basics, and consequent price reduction, to a sophisticated machine with all the features that modern technology can provide.

For makers

The future is promising radical changes in our way of life. The disruption that the Corona Virus is causing is showing that, when everything passes, the world will be different. Many activities that until then were common will cease to exist. The rapid adoption of digital technology, especially the Internet, imposed by the pandemic will prevent us from returning to previous customs.

Stores will disappear, replaced by Internet shopping, events will be virtual and many people will work exclusively at home. However, the human being will not change and when he is in trouble he will still go to a doctor or a hospital. Not only will medical equipment become more sophisticated, but also connected, part of a unique world in which your doctor monitors your body through an interface device.

Respirators or ventilators, oxygen concentrators are examples of equipment that will be part of our future world. You can be the developer, manufacturer, seller, or responsible for maintaining them.