In this series of articles, we start from what the reader should consider when designing an innovative project, its sources of research, the methods to be adopted, problem solving and much more. Now that the readers have reached what they want, have a project on their desk, or on their computer screen, a critical moment has come: to build a prototype.

In engineering, it is common to adopt the phrase "theory is different from practice" and that is what really happens. A perfect “on paper” design, designed without error and even simulated on a computer may not work as intended when we assemble it.

It's not just the way we assemble it or the components we use that impacts the results. It is much more than that. We must take into account a multitude of factors which will shift the tolerances of components used to environmental factors that may change from where we perform testing to where it will work. Regarding the components, we can mention the electrolytic capacitors, for example, can have tolerances of -20 to + 50% and other components can be obtained with equally important tolerance ranges when assembling a project.

In a more critical application, it is convenient to assemble more than one prototype to verify just how small tolerance variations can influence its operation. We also have the layout of the board and the way we prototype it. A non-critical circuit may initially be mounted on a protoboard or even in what was formerly called a “spider” with the components welded directly to one another on a workbench, as shown in Figure 1.

Of course, this does not apply when we are working with a complete circuit or even when using integrated circuits in more advanced technologies where part of the circuit is already ready on a board.

Anyway, all this must be taken into account and it is best to have a planned procedure, adopted by those who understand the subject, as we will see below.

Prototyping

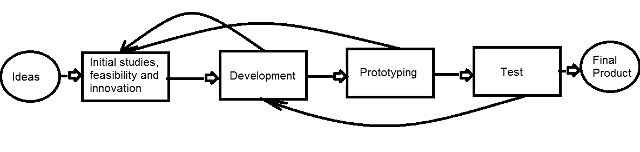

The prototyping, although considered the final phase of a project, before testing, is not really. Through it we can reset any settings for problems which may already appear. As shown in Figure 2, malfunctions that require the redefinition of previous steps may already appear at this pre-test stage.

As we can see, when establishing a sequence of procedures for project development, the steps involved are not exactly sequential. They form a flowchart which eventual turns to earlier stages may occur as a result of what we observe throughout development.

Do not think, for the reader that when developing a project, each step being successfully completed, we can completely forget about it and move on to the next step. It is not quite like this.

A problem that arises there in the final stages may well lead to the need for a return to the previous stages. We must think about this more critically: a problem that comes at a late stage of the project and requires going back to previous steps, depending on what those steps are, can mean too much time and money to disregard.

“Let us know how we solve this problem later, when we get to the end of the project” is something the developer should never do.

In practice, we can say that there are two types of prototyping which should be considered when creating a new product and that depend on several factors.

a) Low fidelity prototyping

In this type of prototyping, we do not need to have the complete product to observe how it works. We can use steps and test how each one works, and only then move on to a final assembly for testing.

For example, when working with projects which use microcontrollers we do not initially need to develop the complete program. We can do the initial tests using sketches (*). In a project involving a load or sensor trigger shield, we can start from ready-made configurations without the need to calculate a specific circuit.

Another feature of this type of prototyping is that the assembly may not interact exactly with the user as expected at an end product. Problems may already appear at this stage or in testing. If the product is simple, this may not be a difficult problem to solve.

Although interesting for relatively simple and non-critical products, this type of prototyping has some advantages. It's simple, the cost is lower depending on the product, it is faster and affordable and the changes are simpler to make. But it also has some drawbacks.

Mounted versions do not accurately depict the actual operating conditions of the product. They are sensitive to external problems which will not occur in a final assembly. The designer may be mistaken in making a prototype assembly that does not work initially, but with a less problematic final version, works perfectly. One should be aware of this kind of problem.

Depending on the type of product such an assembly can lose its practical value by consuming time and money.

b) High fidelity prototyping

In the assembly of the prototype, we should take into account configurations which are as close as possible to the maximum of the final configuration of the product, taking into account all variables that may affect its operation.

Even if an eventual assembly is done by hand, for example on a printed circuit board, it should already take into account a component arrangement that is close to the expected final arrangement for the finished product.

The very elaboration of a final environment for its installation (box, for example) or placement in a device should be predicted at this stage so that, once it works, the final tests can be more realistic.

Of course, there are some factors which should be taken into account in this type of prototyping that may or may not be convenient. The first is that it takes longer.

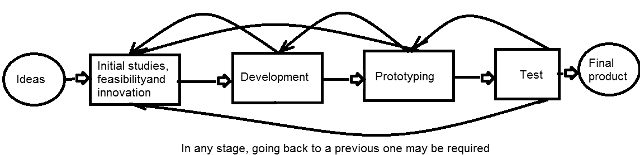

But, as we stated in the case of low fidelity prototyping, as shown in Figure 3, we may waste some time now, but if any problems occur, we have to go back to an earlier stage which may cause us to waste more time.

A little more time in this process can mean gaining more time if we have to go back in the process and redo it all over again.

Using components with actual sizes and shapes (which will be used in the final design) also has the advantage of helping to find problems which will occur when assembling the final product. A component with a shape that interferes with the installation in the box or in the destination may mean the need to redesign the device.

Analyzing the advantages and high fidelity prototyping

A first advantage is that we already have a complete view of how the project will be completed. It will also make it easier to get an idea of ??what kinds of modifications will be needed.

An important fact to note is that while modifications required for low fidelity projects are time consuming, modifications to high fidelity projects typically take less time.

In fact, both techniques can be used in the same project, depending on the designer's approach. We can perfectly start with a low fidelity prototype to simply see "if it works" and once it works, even incompletely moving to a high fidelity prototype.

In this case, the tests must be applied in both phases, the first being an initial test which leads to eventual changes in the layout of the final prototype assembly and in the second phase to lead to the final product.

In short, prototyping is critical in the development of any type of project. To make it a few final recommendations must be made in the style of the maker manifesto.

- If you have a project idea, do it. As important as ityself at some point you will need a prototype.

- Plan well so that the least time is spent and the material cost is also the least.

- Know exactly what to test after your prototype is ready.

- Design and build keeping in mind what the end consumer thinks.

Testing

This is perhaps the most complex phase of a project, both for the variables which come into play and for the responsibility it represents. A failure not detected at this stage can compromise a project in a way that the consequences cannot be predicted.

We can cite as examples products from large companies, such as Samsung's exploding cell phone battery, which has brought huge damage, and also going beyond, as I write this article (2019) the Boing 737 software flaw.

A simple testing step, which could avoid the problem and that has been forgotten, brings huge losses to a company, even a very large one.

For those who are “small”, a failure of this type in a product launched can mean the end of the company.

When planning the tests which will be performed with your product, you must take into account different factors depending on its purpose. A user test is always important and especially product acceptance so that minor flaws can be detected prior to the launching.

If the product will use RF (Radio Frequency) signal transmission, it must be verified that it complies with the standards of the country in which it will be released. This involves testing and certification.

There are companies that do both testing and certification for products, which should be consulted or even contracted for testing.

Basically, the tests involve the following areas which will be explored in a timely manner in new articles.

- Environmental tests - these tests provide data on the product performance in relation to the environment in which it should operate. Note that this takes into account several situations such as weather, dynamic, sealing, durability and temperature testing.

- Testing for medical devices - Medical devices have an additional responsibility to operate to human health to a greater degree, thus requiring special procedures. These tests involve battery life (when applied), EMC (Electromagnetic Compatibility) sensitivity, safety testing and compliance with medical standards.

- Telecom devices - are those that somehow involve the transmission of RF signals. They may also need tests from other categories, for example, medical equipment which uses RF signals. Special and compliance tests must be performed. These tests involve the norms of several countries and technologies such as SAR, Zigbee, RED, NEBS, etc.

- Others - in addition to these, can be included which depend on the manufacturer's responsibility such as accelerated aging test, flammability, component fatigue, dynamic tests, impact, humidity, safety, vibration, etc.

In other articles in this series, we will delve into the subject.