We could include the welder in the category of tools, but its importance is such that we prefer to talk about it separately. We will not go into detail about welding techniques or how a welder works, as they are not part of our objectives with this book

(*) This article is part of our book . Build your own development or maintenance bench

There are dozens of types of soldering irons available that can be part of workbenches depending on the type of work being performed. And, together with soldering irons, accessories that are increasingly becoming more necessary to guarantee perfect welding or desoldering work. In the link below we have the suggested soldering irons, soldering stations and accessories.

The solder

We still find in old applications, repairs and even prototype assemblies the use of common 60/40 solder, which is an alloy of lead and tin in the indicated proportion. This solder is supplied in different types of packaging depending on quantity.

Of course, for field work, cards or small tubes are easier to transport.

However, lead is highly toxic and has been abolished from modern assemblies, opting for lead-free solder. It consists of a copper-based alloy and has a higher melting point, thus requiring a welder that reaches a higher temperature.

The soldering iron

Normally, for beginners or for those who want to have their first soldering rironr, we can start with a low-power type that acquires enough temperature to work with common solder and lead-free solder.

Fine tip welders with powers of up to 60W are recommended for the common bench, as shown in figure 2.

https://www.newark.com/tenma/21-1046/solder-wire-227-deg-1mm-6oz/dp/64M0943

Some types have sets of tips with different thicknesses, necessary when working with SMD components.

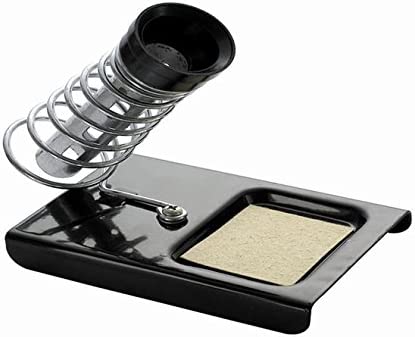

The first important accessory directly connected to the soldering iron is the support to keep it in position on the bench, in which case some types have a small sponge associated, which must be kept moist, to be used to clean the tip. In figure 3 we have an example.

We also have the solder sucker, which is very useful and, in some cases, can be associated with the soldering iron itself. In figure.4 we have a simple sucker.

Of course, the tools we saw are also associated with welding work, such as tongs, spatulas, pliers, etc.

However, a sophisticated way of working with soldering, necessary for more elaborate work and if the reader can invest, is a soldering station. The soldering station consists of equipment that controls the temperature of the welder and has several resources for carrying out the work, such as the inclusion of a sucker, different tips and much more. In figure 5 an example.

In the indicated model we find the control system and the base for placing the welder.