Therefore, before moving on to the bench itself, it is very important that its planning and location are directly associated with this problem that we discuss in this chapter.

Sensitive components, integrated circuits and even boards can be damaged even in the process of removing them from packaging. ESD or Electrostatic Discharge will be the subject of this chapter. In nature, the tendency is for bodies to remain neutral, that is, with an equal number of positive and negative charges, as shown in figure 1.

In practice, however, this is not what happens. Various phenomena can break this balance and charges of a certain polarity can prevail, causing different types of problems when neutrality is reached again. This occurs because this neutrality is achieved with a discharge or strong movement of these charges, as shown in figure 2.

The imbalance of these charges can reach values so high that the bodies in which this occurs will be subjected to voltages of hundreds or thousands of volts. A person walking on a carpet can accumulate charges in their body at a potential that can easily exceed 10,000 V.

In high school courses we learned that we can break the electrical balance of a body by friction, contact or induction. For electronics professionals, it is necessary to know how to restore balance to prevent it from causing damage to electronic components and circuits. Figure 3 shows what happens in the three cases.

But what are the ways that professionals who need to work in dry places with sensitive components should use to prevent static charges problems?

Grounding

Any charged body connected to earth discharges, as suggested in figure 4.

A professional who handles plastic parts and is isolated from the ground (insulating floor or carpet) can accumulate hundreds or thousands of volts during his work. The most adopted solution in cases like this is to ground the operator. For this purpose, we have several procedures that can be adopted.

One of them consists of using grounding bracelets or shin guards, as shown in figure 5.

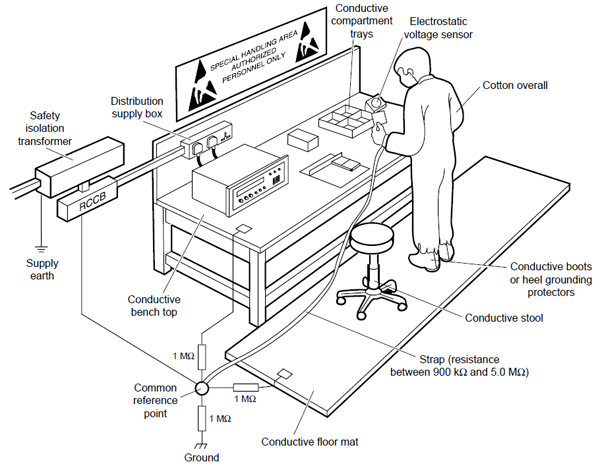

All workbenches, shelves and other locations that could potentially present the possibility of a build-up of static electricity must be grounded. In figure 6 we have a figure that illustrates these locations.

Troquei esta figura por um da internet com os termos já em inglês

It is necessary to consider that some procedures that are accepted as sufficient to eliminate loads may not be. For example, if we land a professional, the charges accumulated on their clothing may not be eliminated. In fact, certain materials used in clothing are such poor conductors of electricity that even if the person is grounded, the clothing still maintains a charge, as shown in figure 7.

See that grounding is efficient when there is a path for all the charge accumulated in a body to flow to the earth.

It is also very important to identify the protected area (EPA – ESD Protect Area) so that people working there are aware that some special precautions need to be taken when components and circuits are handled. Note that work surfaces must be able to dissipate static charges and still be grounded. All operators must ensure that their bodies and clothing do not store electrical charges.

Components and circuits must be stored in places that do not accumulate static electricity and even their packaging must be capable of dissipating it. These packaging will be covered in our next chapter.

How to Troubleshoot ESD problems

Are electronic components, expensive boards and equipment that use ESD-sensitive components presenting constant problems on dry days due to accumulated charges? It's time to try to identify the problem to find the best solution.

To identify the problem more precisely, there are instruments capable of locating static charges. In figure 8 we have a locator specially designed for this purpose.

This type of locator not only gives an idea of the intensity of the charges but also of their polarity, thus allowing the necessary measures to be taken to eliminate them.

Once the problem has been identified, you must proceed to eliminate it. To do this, you must think about both grounding and the possibility of using ionization equipment. If the body that manifests the charges is completely conductive, grounding solves the problem. However, if it is partially conductive with insulating areas, then you must think about the solution provided by the ionizer.

Of course, there are cases where both solutions must be considered.

Standards

The standards below that govern procedures to avoid or correct ESD problems are:

Project. 1131 003 – Basic Requirements for the Protection of ESD-Sensitive Components

There are IEC standards from the IEC130 series that must be analyzed when it comes to ESD protection:

Antistatic packaging

Many electronic components and circuits are extremely sensitive and are easily damaged by the presence of static electric charges. This requires special care in handling, transportation, and storage. A special item in the protection of these components is antistatic packaging.

The simple friction of your shoes with a carpet can generate electrical charges that take your body to potentials that can reach 10,000 V. A discharge of this voltage on an electronic component or board can cause irreversible damage.

The charge present in objects with which the components come into contact may be responsible for discharges capable of causing irreversible damage. The thin oxide layers of CMOS technology components cannot withstand more than a few volts and can be broken, leading to failure.

There are several ways to protect components during handling, transport and storage and one of them is through anti-static packaging. Made with special materials, these packaging prevent the storage of electrical charges, thus serving to protect components and boards.

Practically all components and boards use this packaging nowadays, being a fundamental item in the electronics laboratory, in the store or simply when transporting a sensitive electronic device.

Today we can have packaging of this type at affordable costs, which allows it to be available to everyone, in all possible formats and sizes. Before we discuss their availability, let's see how they work.

Antistatic packaging

The most common material used in the manufacture of antistatic packaging is polyethylene terephthalate or polyethylene terephthalate (PET). It is a synthetic polymer, a plastic that, in addition to being able to be molded by heat, also has important electrical properties.

For packaging we have the silver color types that consist of metallic film and the pink or black color that consists of polyethylene. This form of polyethylene can also be worked into the form of foam, bubbles or plastic.

For electronic components and boards, the most commonly used form is metallized PET film bags, as shown in figure 9.

These bags have an important electrical property, which is that they do not accumulate charges, which is why they are called antistatic or dissipative.

Dissipative anti-static packaging or bags, as the name suggests, are made from standard polyethylene with a static dissipative coating or layer on the plastic. This prevents the accumulation of a static charge on the surface of the material, as it discharges easily.

To make the material conductive, we add a tallow amine to the surface of the bags that attracts moisture, making it slightly conductive, thereby carrying any charges that are accumulating to another surface, or to the atmosphere itself. Note that this material is antistatic, in the sense that it hinders the formation of static charges, but it is not immune to electrostatic discharges.

However, if a charged object touches the material (such as a person's hand), its charge will easily be transferred to the material and its contents. These packages are typically pink or red in color because of the dissipative chemical layer.

There are also black bags, where polyethylene is manufactured containing traces of carbon, forming partial but not complete shielding.

Anti-static conductive bags are manufactured with a layer of conductive metal, usually aluminum, and a dielectric layer of plastic covered by a static-dissipating coating. This forms a non-conductive shield and barrier, protecting the contents from static charge like a Faraday cage.

These packages are preferred for the most sensitive components but are also used in environments where sparking would be dangerous, such as oxygen-rich areas on aircraft and hospitals.

Metallized packaging is more fragile than non-metallic packaging, however, as any perforation compromises the integrity of the shield. Furthermore, they have a limited lifespan as the metal substrate can deteriorate over time.

These bags are usually gray or silver due to the metal layer, although they are still transparent to some extent.

Conclusion

Protecting your components and boards doesn't cost much. A very small investment in appropriate packaging can avoid the loss of a much more valuable component and, nowadays, difficult to replace in a short period of time.

Think about having a stock of these packaging in sizes according to the components and products you work with. For more information, we suggest contacting Latere.